0086-379-64087240

The waste evaporates, sublimates and organic waste is decomposed by microorganisms to release harmful gases to pollute the atmosphere; The fine particles and powders in the waste drift with the wind and diffuse into the air, causing dust pollution of the atmosphere; In the process of waste transportation, storage, utilization, treatment and disposal, harmful gases and dust are produced. Hazardous waste may cause toxicity through ingestion, inhalation, skin absorption, and eye contact, or cause dangerous events such as combustion and explosion; Long-term hazards include long-term poisoning, carcinogenesis, teratogenesis, and mutagenesis caused by repeated contact.

Hazardous waste will do harm to society, the environment, and people, so it must be treated innocuously. At the same time, many private factories do not have the qualification and ability to deal with hazardous waste, so they must entrust the units with the qualification to deal with hazardous waste approved by the state. This is responsible for the environment and the safety of everyone's life. The following is the application of our equipment in two hazardous waste treatment methods.

Incineration furnace is a comprehensive process of solid waste decomposition at high temperatures and deep oxidation. The advantage is that a large number of harmful wastes are decomposed into harmless substances. Because the proportion of combustible materials in solid waste increases gradually, the incineration method is used to treat solid waste, and it has become a necessary trend to use its heat energy. In this way, solid waste occupies less land and has a large amount of treatment. The incineration plant is equipped with an energy recovery system. The heat obtained from incineration can be used for power generation, etc.

Our cement rotary kiln incineration system can handle industrial waste, medical waste, chemical waste, polluted soil and radioactive waste. Moreover, we have developed a new hazardous waste incineration system in the waste treatment field. This system is a new generation of environmental-friendly incineration systems developed by using the latest research results. Compared with traditional incineration technology, this system can fully meet stringent environmental regulations in the future.

According to the different demands of customers, we can provide three types of furnaces, which are slag type, non-slag type and pyrolysis type. Our rotary kiln incineration furnace can handle industrial waste, medical waste, chemical waste, polluted soil and radioactive waste. Ball mill solid waste grinding is widely used in iron smelting, pelletizing, metal recovery, iron powder, and chemical raw materials. Choose CIC as your direct China rotary kiln manufacturer.

Slag Type | Non-slag Type | Pyrolysis | |

Material Range | wide① | wide | relatively wide |

Material Status | solid, liquid, gas | solid, liquid, gas | solid, liquid, gas |

PCC Temperature | 1200—1450℃ | 850——900℃ | 500——700℃ |

SCC Temperature | >1200℃ | >1200℃ | >1200℃ |

Wearable Material Lifespan | short | long | long |

Residence Time | short | long | relatively long |

Auxiliary Raw Material | yes | no | no |

Auxiliary Fuel | more | few | few |

Slag Burning Rate | low | relatively low | high |

Slag Treatment | no③ | yes | yes |

Smoke Emission | high NOx | low NOx | low NOx |

Operating Cost | high | low | low |

Notes:

①Suitable for handling high-toxic wastes.

②Suitable for handling organic wastes.

③It can be used as paving material after the SPP process.

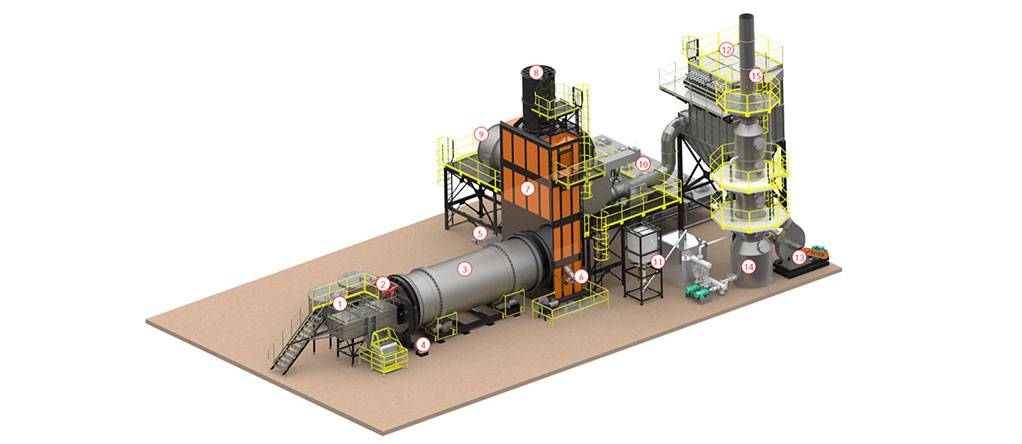

Incineration System

The rotary kiln incineration system is ideal for handling industrial hazardous wastes. It can handle not only solid, liquid, and gaseous hazardous waste but also sludge. We can provide a whole set of incineration equipment (including feeding system, rotary kiln, secondary combustion chamber and slag discharge system) as well as EPC services. We can formulate different flue gas treatment systems according to different emission requirements to ensure that the flue gas emissions comply with local environmental regulations.

Incineration System Illustration

Grinding Method

The waste is crushed a second time, and the moisture is heavy, and the monomers of various components are separated to create conditions for the next separation.

Grinding a variety of waste materials and mixing them evenly at the same time.

Manufacturing waste powder, increase the specific surface area of materials, accelerate the speed of chemical reaction of materials.

Experimental Equipment

Our process research and testing center are equipped with special thermal test equipment, which can make simulated experiments on the materials according to different process requirements. Through the measurement of various parameters, it has laid a solid foundation for the optimization and operation of the entire thermal system.

Spare Parts Supply and Service

We can provide the following services:

The measurements and manufacture of spare parts.

Online inspection and adjustment of rotating kiln's status.

Lifecycle equipment control system.