0086-379-64087240

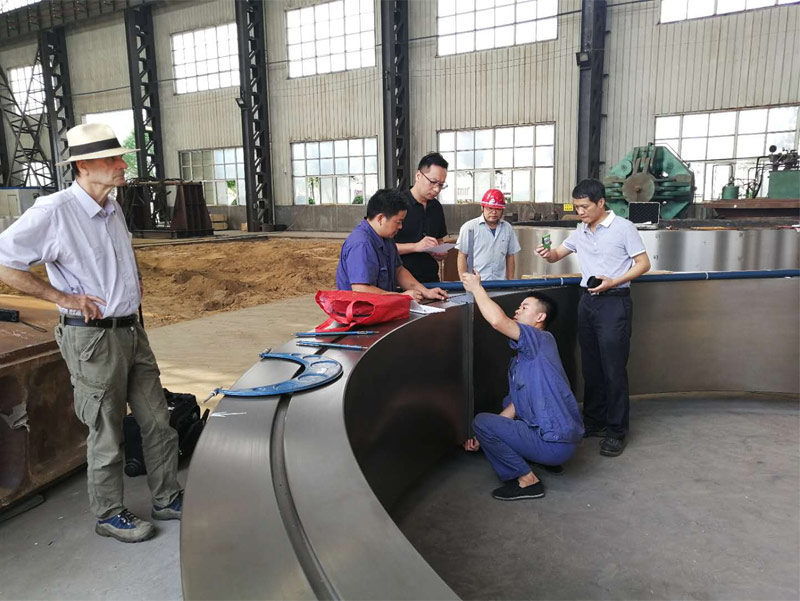

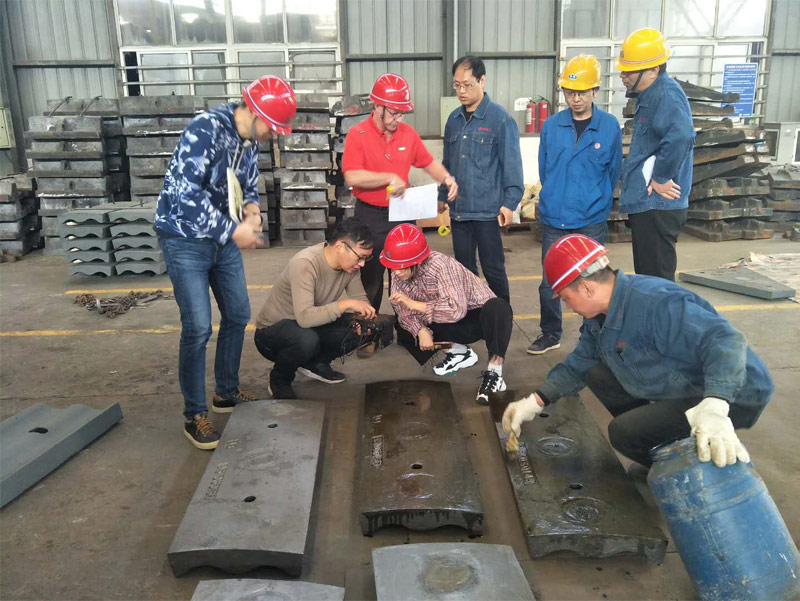

CIC has a complete technical inspection and maintenance team. Before the equipment is delivered, we will carry out mill inspection and kiln inspection according to the requirements of customers to ensure the quality of products. After the equipment is delivered, in addition to going to the site for installation, we will also train for the clients' operation and maintenance.

In order to guarantee the quality of the industrial grinding mill, CIC insists on implementing strict testing on each of the ball mill machine and accessories. The advantage of CIC's testing is based on:

Experienced Testing Stuff

CIC has more than 200 engineering technical staff, 6 of which are senior engineer and 59 are Engineer. Among all these engineering and technical staff, tens are professional quality control staff, taking charge of the testing of the products for years, to make sure each of the overflow ball mill, wet grid ball mill and dry ball mill confirms to the standard requirement of the technical agreement and so on.

Inspection of Girth Gear for Turkish Customer

Inspection for DELTA MARIN Corp.(Marine Parts)

Inspection of Dryer Tyre for Indonesian Customers

Inspection for Kiln Tyre of India KHD

Inspection of Ball Mill Liner for Australian FFF

Inspection for Australian Customer

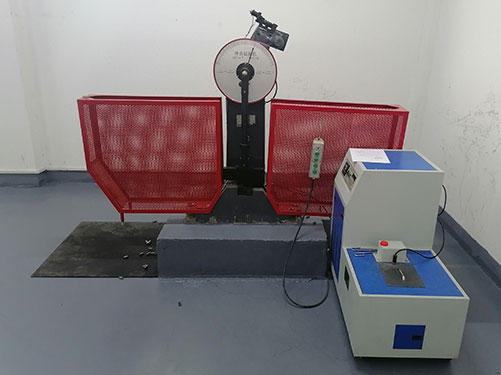

CIC possesses tens of advanced inspection and testing equipment and is capable to manage most of the regular testing on CIC's products and issue the relevant testing reports. The equipment CIC possesses includes the Ultrasonic Fault Detector, Universal Hardness Tester, X-Ray Nondestructive Flaw Detector, Rotating Magnetic Field Detector, Multi-purpose Magnetic Powder Flaw Detector, Thickness Guage, 3 Meter Metroscope with the precision of 1/1000 mm, Angular Instrument with the minimum measurable angle of 2 seconds, Gear Tooth Form Tester, Gear Hob Tester, Electronic Universal Material Testing Machine, High-Frequency Fatigue Testing Machine, etc.

Mechanical Impact Tester

Mechanical Tensile Tester

Universal Hardness Tester

Ultrasonic Fault Detector

X Ray Nondestructive Flaw Detector

Df100 Direct Reading Spectrograph

CIC Quality Control Department is the specialized department, being responsible for product quality. What's more, CIC cooperates with the national authorized testing institutes, such as the CITIC IC Engineering Design Institute, ZYS Luoyang Bearing Science & Technology Institute, the Luoyang Ship Material Research Institute (known as the 725 Institute), etc.

CIC taking them as the third party testing institute and their testing seriously as part of the testing procedure.

CIC will track the whole process of the products sold, and regularly summarize the after-sales service problems, treatment results and cause analysis of the products. On the one hand, CIC will complete the maintenance work of the products through the training of the owner's personnel. On the other hand, CIC's professional technical maintenance team will carry out on-site inspection and repair for the problems that customers are difficult to handle by themselves, as well as follow up the whole process of repair. We will record and sort out major or frequent quality problems in combination with overflow ball mill, wet grid ball mill and dry ball mill maintenance feedback information and establish complete quality files for each product and corresponding problems.

Maintenance of Chemical Light Gray Kiln

Repair On-site

Repair and Maintenance

Maintenance Ball Mill