Introduction of Semi Autogenous Grinding Mill

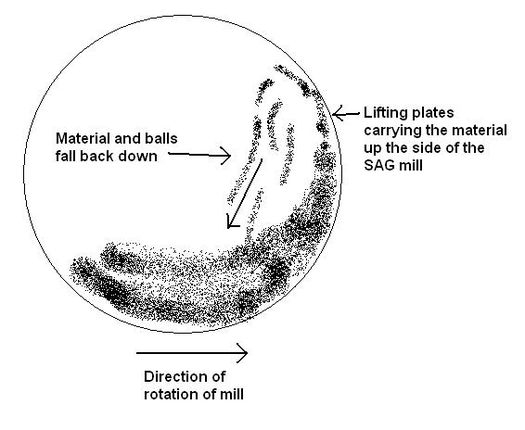

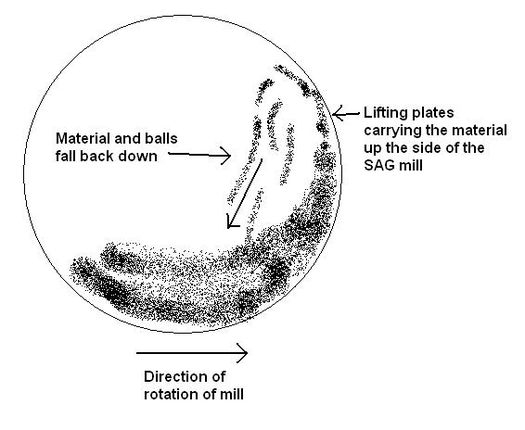

Like ball mill and rod mill, SAG mill also belongs to horizontal placed cylinder grinding equipment, the working principle is basically the same, which by means of processed material itself (or add a small amount of medium) in the simple body of continuous impact, rolling grinding and make the material crushing. The filling rate of steel ball in the shell of the semi-autogenous mill is a main item to distinguish SAG mill and autogenous mill. In order to eliminate the impact of the accumulation of rock, the autogenous mill allows to add about 3% of the ball (Φ80 ~ Φ120), SAG mill steel ball filling is generally 8% ~ 12%, even up to 15%.

Advantages of Semi Autogenous Grinding Mill

The full range of specifications and wide range of applications enable SAG mills to perform grinding operations with fewer configurations than conventional mills. This helps to reduce the investment and maintenance costs of the SAG mill circuit.

The scope of application is wide due to complete specifications of SAG mill. The semi-autogenous mill can be equivalent to two or three stage crushing and screening, rod mill, and part or all of the ball mill grinding operation effect.

SAG mill is also the best solution for wet grinding. In this regard, the crushing and screening process is difficult to complete.

From circuit design to operation and optimization, our process experts help you create an efficient heavy equipment and machinery automated process that ensures the grinding results you expect.

Through automatic operation, electricity can be saved, grinding medium and liner consumption can be reduced while increasing production capacity.

Unique grinding expert system can comprehensively monitor the real-time operation of the SAG mill, grinding status, and material parameters. Through computer control system, make the man-machine interaction effectively, save manpower and improve accuracy and capacity.

Learn more about the Intelligent Grinding Expert System

According to professional data sources, by far the largest SAG mill is 42' (12.8m) in diameter, powered by a 28 MW (38,000 HP) motor. While CIC is currently capable of manufacturing SAG mills with a maximum diameter of 21' (6.5m)

SAG mill is being processed by us for Russian customers

Packing and Delivery

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland  日本語

日本語