CIC Achievement in Sewage Sludge Dryer Machine

CIC has successfully applied this technology to multiple sludge dewatering centrifuge with great success.

CIC sludge drying machine equipment be used in the wastewater treatment plant of Geweite Environmental Protection New Energy Co., Ltd.

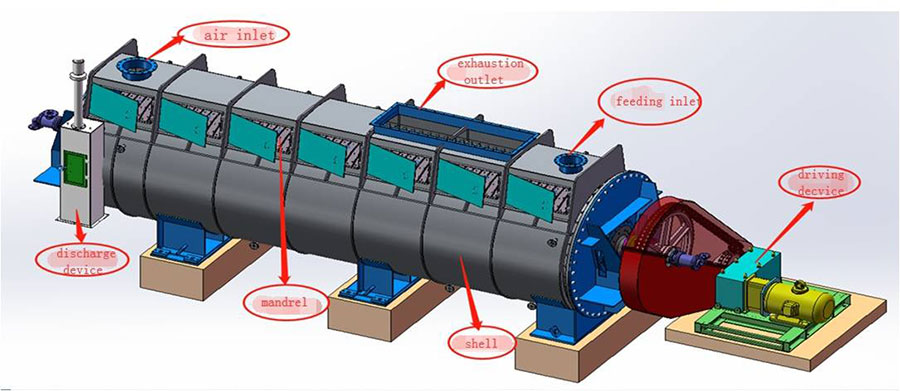

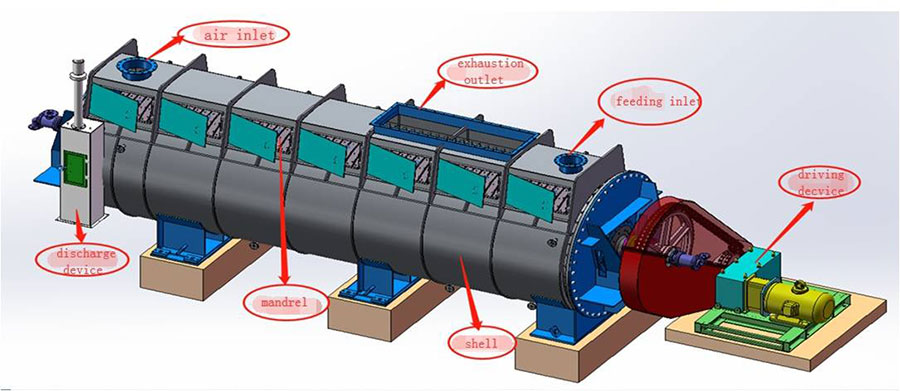

Principle of Rotary Sludge Dryer Machine

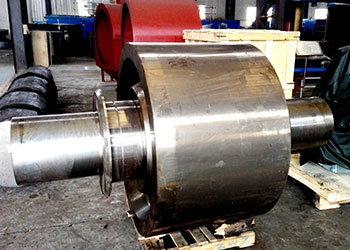

In CIC heavy equipment companies, The working principle of the sludge drying machine is to transfer the material (wait to dry) into the sealed chamber from the inlet and use the saturated steam as the heat source to heat the material indirectly. Through the hollow shaft components (disc, feather root, mud scraping stick), it can fully stir and push the material to make the water evaporate faster, so as to achieve the purpose of drying the material by sludge treatment and disposal.

The treated materials for sludge drying machine equipment include industrial sludge, domestic sludge, mixed sludge, etc.

Technical Parameter of Sludge Dryer Equipment

Capacity | 70-100 t/d |

Moisture content before process | 80% |

Moisture content after process | 40% |

Main motor power | 90 kw |

Reduction ratio | 1:55 |

Rotate speed of hollow shaft | 0~10 rpm |

Diameter of hollow shaft | φ 750 |

Diameter of disc | φ 2100 |

Heat transfer area | ~41 m2 |

Heat source | saturated vapor |

Working pressure | 0.5 Mpa |

Working temperature | <170℃ |

Size of machine | ~11700×2900×3500 |

Weight of machine | ~65 ton |

The Significance of Sludge Dryer Machine

Increasing the solid content of the sludge can reduce the volume of the sludge

Municipal sludge with a solid content of more than 85% can be stored stably for a long time

The sludge with solid content of more than 85% can meet the US EPA-503A standards

Municipal sludge with solid content ≥40% can meet the requirements of fluidized bed incinerator; municipal sludge with solid content ≥90% can be used as an alternative fuel

The rotary kiln incineration system we provide can be used for processing:

Hazardous waste

Industrial waste

Petrochemical waste

Medical waste

Radioactive waste

Contaminated soil

Item | Design value | Maximum value |

calorific value(kj/kg) | 12560~20934 |

Cl(%) | <2 | 5 |

F(%) | <0.4 | 1 |

S(%) | <2.5 | 3 |

Related Issues of Sludge Dryer Machine

What other equipment is there in the waste incineration system?

Rotary lime kiln is one of the key equipments in the waste incineration system, which is also one of the best way to treat all kinds of wastes harmlessly.

CIC's rotary kiln are widely used in dealing all kinds of solid, liquid and gas wastes, including industrial wastes, chemical wastes, pharmaceutical wastes, medical wastes, contaminated soil, radioactive substances and sludge, sludge, etc.

Can you give a brief introduction to the waste treatment system of rotary kiln?

The rotary kiln incineration system is ideal for handling industrial hazardous waste. It can handle not only solid, liquid and gaseous hazardous waste, but also sludge.

We can provide a whole set of incineration equipment (including feeding system, rotary kiln, secondary combustion chamber and slag discharge system) as well as EPC services.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland  日本語

日本語