0086-379-64087240

Vertical mill and ball mill are common large-scale mining grinding machines, which have been widely used in metallurgy, coal, cement, mining and other grinding operations. For a long time, the ball mill has dominated the grinding operation. Until the development of vertical grinding in the 1970s, the grinding technology was raised to a new level.

Vertical mill is mainly applicable to the processing of ultra-fine powder of medium and low hardness non-flammable and explosive brittle materials, while ball mill is the equipment for crushing materials after they are broken. The vertical mill belongs to the grinding equipment of "bed crushing", which is very different from the ball mill of "single particle crushing"

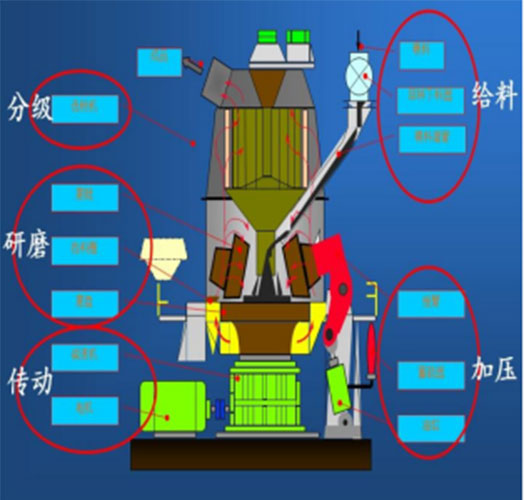

1.Energy consumption: The energy consumption utilization rate of ball mills is very low, and it is currently being replaced by vertical mills, roller presses and other equipment. When the raw material grindability and product particle size are the same, the power consumption of the vertical mill is lower than that of the China ball mill. Because the grinding method of the vertical mill is reasonable, the grinding power is fully utilized and the classification is timely, which avoids the phenomenon of over-powdering of materials, so the grinding efficiency is relatively high.

2. Process:The process flow of the vertical mill is relatively simple. It mainly uses air flow to transport materials directly through the separator, saving the cost of the powder separator and elevator. In addition, the vertical mill base construction investment is small, the failure rate is low, the operation efficiency is high, the layout is compact, the building area is larger than the ball mill, and the building space is wider than the ball mill. There are many advantages. Therefore, the ball mill is limited by the larger steel ball diameter and can only feed smaller raw materials.

3. Grinding efficiency:The vertical mill combines grinding, classification and drying into one, and is superior to ball mills in terms of grinding efficiency. The vertical mill has a short changeover time and can change different raw materials on the same mill in a very short time to produce different products. In addition, the vertical mill also uses hot air flow to transport materials. When crushing materials with relatively large moisture content, the inlet air temperature can be controlled to ensure that the product reaches the corresponding moisture content. The vertical mill can dry most of the water. On the contrary, the intelligent drying function of the ball mill is weaker.

4. Product mass: Since the vertical mill takes a short time to classify the finished powder, over-grinding is avoided. Therefore, compared with the ball mill, the product of the vertical mill has a higher degree of homogenization and purity. In addition, the vertical mill has a different working principle. There is no direct metal contact during operation, which causes less pollution to the finished materials. The vertical mill can conveniently and quickly adjust the separator speed, wind speed and grinding roller pressure to adjust the product fineness, and the impact on the whiteness of the mineral when grinding white minerals is much smaller than that of a ball mill.

The vertical mill is not suitable for grinding hard and corrosive materials. It has a short life and requires frequent maintenance. The wear parts are more expensive than the wear parts of the ball mill, but the total maintenance amount of the ball mill, powder separator and other equipment it replaces is comparable. Maintenance still appears simple, easy and requires less work than it does.