Search

0086-379-64087240

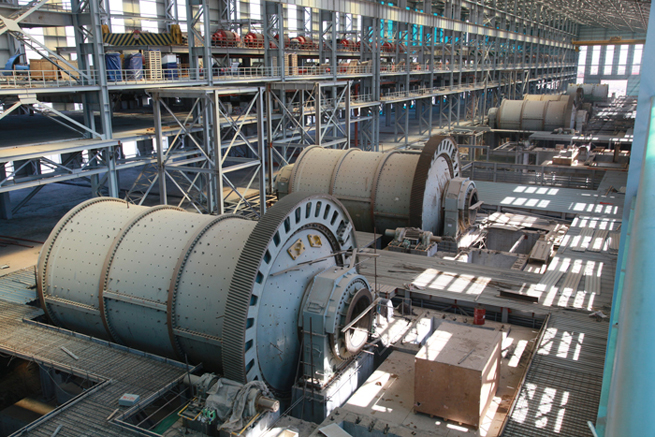

The difference in discharge concentration between grid type and overflow ball mill is mainly due to their different internal structures and working principles.

The ball grinding machine has a lattice plate inside, and the ore enters the mill through the lattice plate. After being ground into smaller particles, the slurry is discharged through the lattice plate. The lattice plate restricts the flow rate of the slurry, which causes the ore to stay in the machine for a longer period of time. This can result in more mineral particles being ground, but can also reduce the processing capacity of the mill. Because the lattice plate restricts the flow rate of the slurry, the discharged slurry contains more solid particles, resulting in a higher discharge concentration in the grid type ball mill.

The overflow type ball mill, on the other hand, has no lattice plate. The ore enters the mill through the feed port, and the slurry is discharged through the overflow port after being ground into smaller particles. Since there is no lattice plate to restrict the flow rate, the processing capacity of the overflow type ball mill is higher than that of the grid type ball mill. However, this can also result in a lower discharge concentration in the overflow type ball mill due to the slurry containing fewer solid particles.

It is important to note that discharge concentration is not the only performance indicator for ball mills. Factors such as processing capacity, energy consumption, and maintenance costs should also be considered. When selecting a ball mill supplier for specific applications, it is important to consider the characteristics of the mineral and production requirements.

Contact Us

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland